Later this decade, the supply and demand of electrical steel may have an impact on EV prices.

March 29, 2023 By Omal J

(Image Credit Google)

Image Credit: General Kinematics

The current debate over the production of electric vehicles has largely centered on where to get lithium for the batteries. Yet, electrical steel, a crucial component for EVs, may become scarce in the upcoming years. To compete in a market that is dominated by foreign companies, US manufacturers are seeking to increase production.

At the end of this decade, analysts predict that there may not be enough electrical steel available globally to meet the demand for electric vehicle motors. To prevent a shortage that would drive up EV prices just when we need them to be cheaper, new businesses are flooding the market.

Ultra-thin sheets that convert electrical energy into mechanical power make up electrical steel. The rotating motors that power appliances like air conditioners, power transformers, and washing machines are built around cores made of standard electrical steel. Although they use the same basic idea, high-grade electrical steel, which is more difficult to come by, is needed for electric car motors and scientific measurement equipment.

Making high-grade electrical steel is a rigorous process, with lead times often nearing a full year, according to a Wall Street Journal story. Companies can't just purchase their way into the industry since it requires stamping and stacking steel and silicon into precise geometries that are occasionally under a quarter of a millimeter thick.

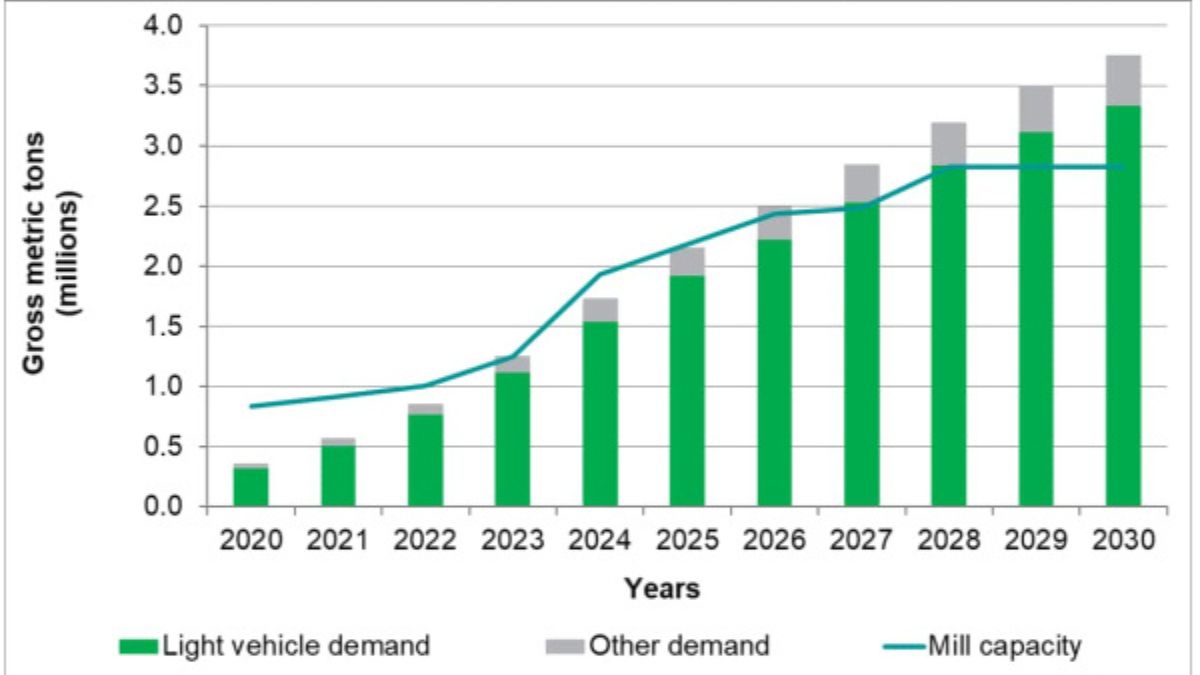

Image Credit: Green Car Congress

Image Credit: Green Car Congress

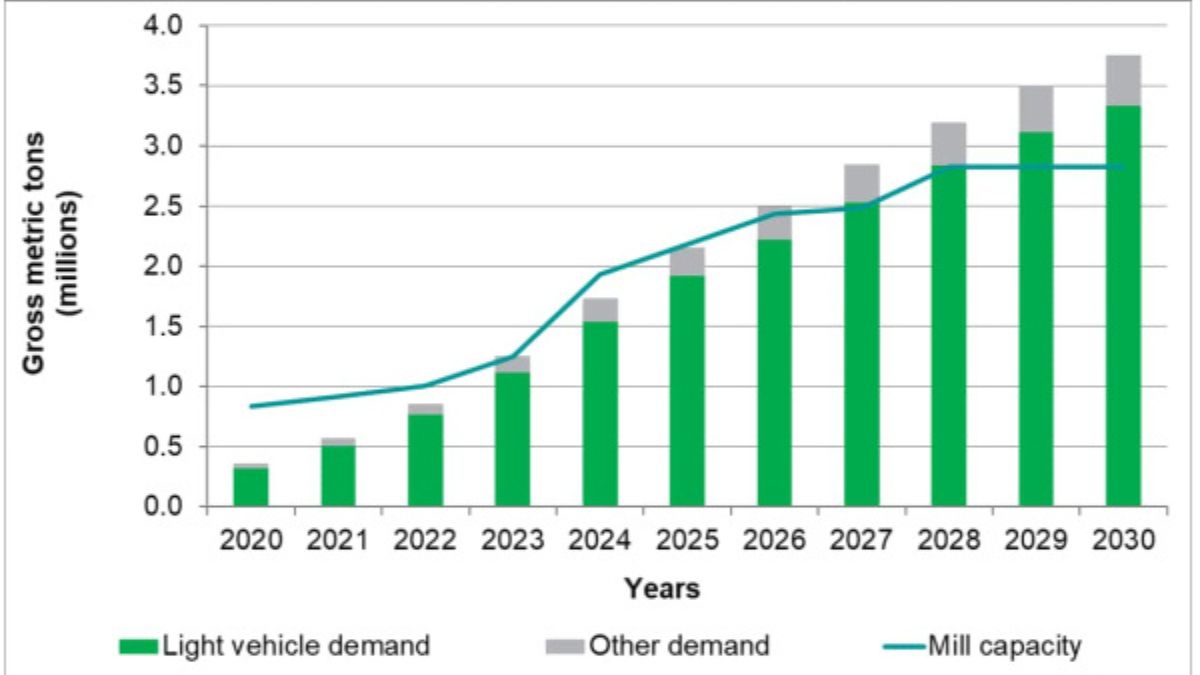

Currently, China, Japan, and South Korea make up the vast majority of the world's supply of electrical steel, all of which, according to analysts, are subject to US steel import duties. Furthermore, by 2027 and by over a million tonnes by 2030, the demand for high-quality electrical steel could be greater than the supply globally.

To narrow the deficit and improve the nation's competitiveness in this specialized industry, American firms like Cleveland-Cliffs Inc. and US Steel Corp. are investing millions to construct new electrical steel mills. By year's end, the business hopes to have a mill operating. Yet, it will probably take several years for domestic manufacturers to gather the tools and know-how necessary to dramatically boost supply. The ensuing circumstance might put negative pressure on EV production.

Read More: Europe ICE Ban 2035: According to New EU Law, No More Gas and Diesel Sales in the Following Decade

The analysis stands in contrast to reports of declining costs for other EV raw materials, which will make the vehicles less expensive in the immediate future. Prices for EV battery parts like copper and lithium have decreased by about 20% since January. With five pricing modifications this year, Tesla has distributed the savings to customers. Uncertainty surrounds the duration of the crisis and what would occur if electrical steel became scarce.

By Omal J

I worked for both print and electronic media as a feature journalist. Writing, traveling, and DIY sum up her life.

Image Credit: Green Car Congress

Currently, China, Japan, and South Korea make up the vast majority of the world's supply of electrical steel, all of which, according to analysts, are subject to US steel import duties. Furthermore, by 2027 and by over a million tonnes by 2030, the demand for high-quality electrical steel could be greater than the supply globally.

To narrow the deficit and improve the nation's competitiveness in this specialized industry, American firms like Cleveland-Cliffs Inc. and US Steel Corp. are investing millions to construct new electrical steel mills. By year's end, the business hopes to have a mill operating. Yet, it will probably take several years for domestic manufacturers to gather the tools and know-how necessary to dramatically boost supply. The ensuing circumstance might put negative pressure on EV production.

Read More: Europe ICE Ban 2035: According to New EU Law, No More Gas and Diesel Sales in the Following Decade

The analysis stands in contrast to reports of declining costs for other EV raw materials, which will make the vehicles less expensive in the immediate future. Prices for EV battery parts like copper and lithium have decreased by about 20% since January. With five pricing modifications this year, Tesla has distributed the savings to customers. Uncertainty surrounds the duration of the crisis and what would occur if electrical steel became scarce.

Image Credit: Green Car Congress

Currently, China, Japan, and South Korea make up the vast majority of the world's supply of electrical steel, all of which, according to analysts, are subject to US steel import duties. Furthermore, by 2027 and by over a million tonnes by 2030, the demand for high-quality electrical steel could be greater than the supply globally.

To narrow the deficit and improve the nation's competitiveness in this specialized industry, American firms like Cleveland-Cliffs Inc. and US Steel Corp. are investing millions to construct new electrical steel mills. By year's end, the business hopes to have a mill operating. Yet, it will probably take several years for domestic manufacturers to gather the tools and know-how necessary to dramatically boost supply. The ensuing circumstance might put negative pressure on EV production.

Read More: Europe ICE Ban 2035: According to New EU Law, No More Gas and Diesel Sales in the Following Decade

The analysis stands in contrast to reports of declining costs for other EV raw materials, which will make the vehicles less expensive in the immediate future. Prices for EV battery parts like copper and lithium have decreased by about 20% since January. With five pricing modifications this year, Tesla has distributed the savings to customers. Uncertainty surrounds the duration of the crisis and what would occur if electrical steel became scarce.